Surface Finishing

At Vormetal, we understand that surface finish is just as critical as dimensional accuracy—whether for functional performance, protective durability, or visual appeal. That’s why we offer a comprehensive range of in-house and partner-based surface finishing solutions to match the technical and aesthetic requirements of your die-cast components.

Our surface treatments are carefully selected and executed to enhance corrosion resistance, improve wear properties, meet industry standards, and align with your product’s branding or end-use environment.

Comprehensive Surface Treatment Options

We offer a full range of surface finishing processes suitable for aluminum and zinc die castings. Each process is carefully monitored to maintain consistency, adhesion quality, and finish uniformity across high-volume production runs.

- Shot Blasting & Tumbling: For surface cleaning, deburring, and preparation

- Anodizing (for aluminum): Adds corrosion resistance and a clean, matte or colored finish

- Powder Coating: Durable, uniform finishes in a wide range of RAL colors

- E-Coating: Electrically applied corrosion-resistant coating for complex geometries

- Zinc Plating: Ideal for increased corrosion resistance on zinc components

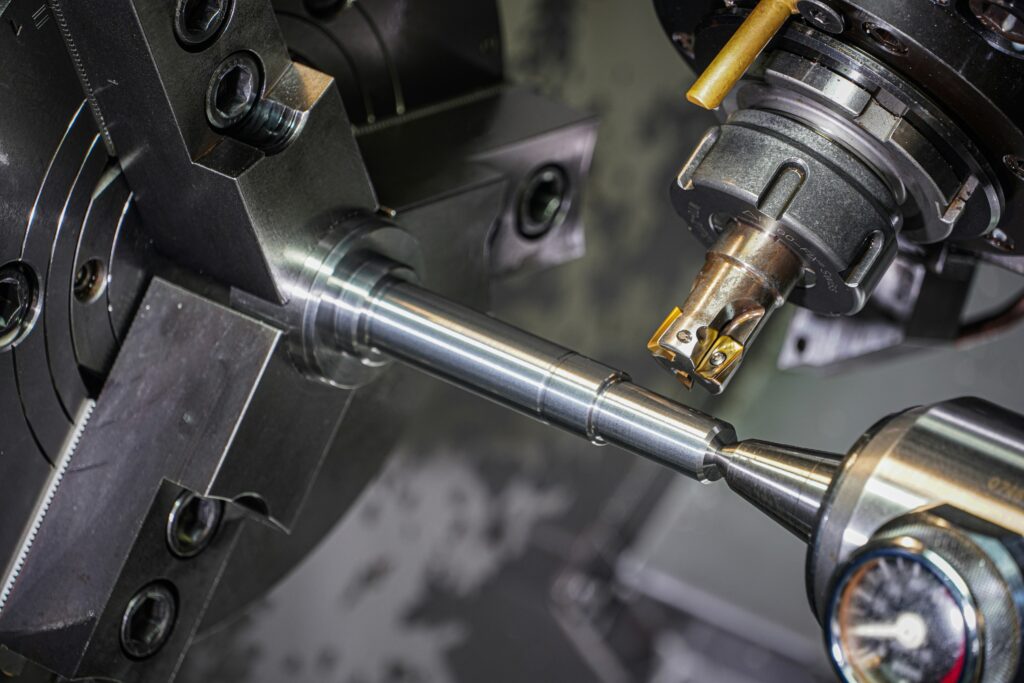

- Machined Finishes: Fine CNC passes for cosmetic flatness or mechanical interface requirements

Applications and Benefits

Whether your application calls for rugged industrial durability or sleek consumer-grade presentation, our finishing options are tailored to suit. Surface finishing improves both the functional lifespan and visual consistency of your parts while helping your product meet regulatory and environmental compliance requirements.

- Enhanced corrosion and wear resistance

- Improved adhesion for paints and coatings

- Controlled surface roughness for sealing or friction-sensitive components

- Aesthetic customizations for brand-specific design requirements

Integrated Into Our Workflow

Our surface finishing processes are tightly integrated with our casting and machining workflows to ensure smooth transitions between stages, reduced handling, and consistent part traceability. Whether finishing is applied in-house or with one of our certified partners, Vormetal maintains full quality oversight at every step.

Request a Consultation

If you have specific surface requirements or are looking for guidance for your die-cast parts, our team is here to help. We offer technical consultation to match finish specifications to your industry, application, and budget.