Quality Assurance

At Vormetal, quality assurance is not a final checkpoint — it is embedded into every step of our manufacturing process. From initial design consultation through to final inspection and delivery, we maintain strict controls to ensure every part meets the highest industry standards and customer expectations.

Our integrated quality management system supports continuous improvement, full traceability, and reliable performance across every project, regardless of volume or complexity.

Our Approach to Quality Assurance

- Early-stage design reviews and manufacturability analysis

- Material certification and supplier quality audits

- In-process inspection at key production stages

- Final inspection including dimensional verification and surface assessment

- Full traceability of materials, processes, and inspection records

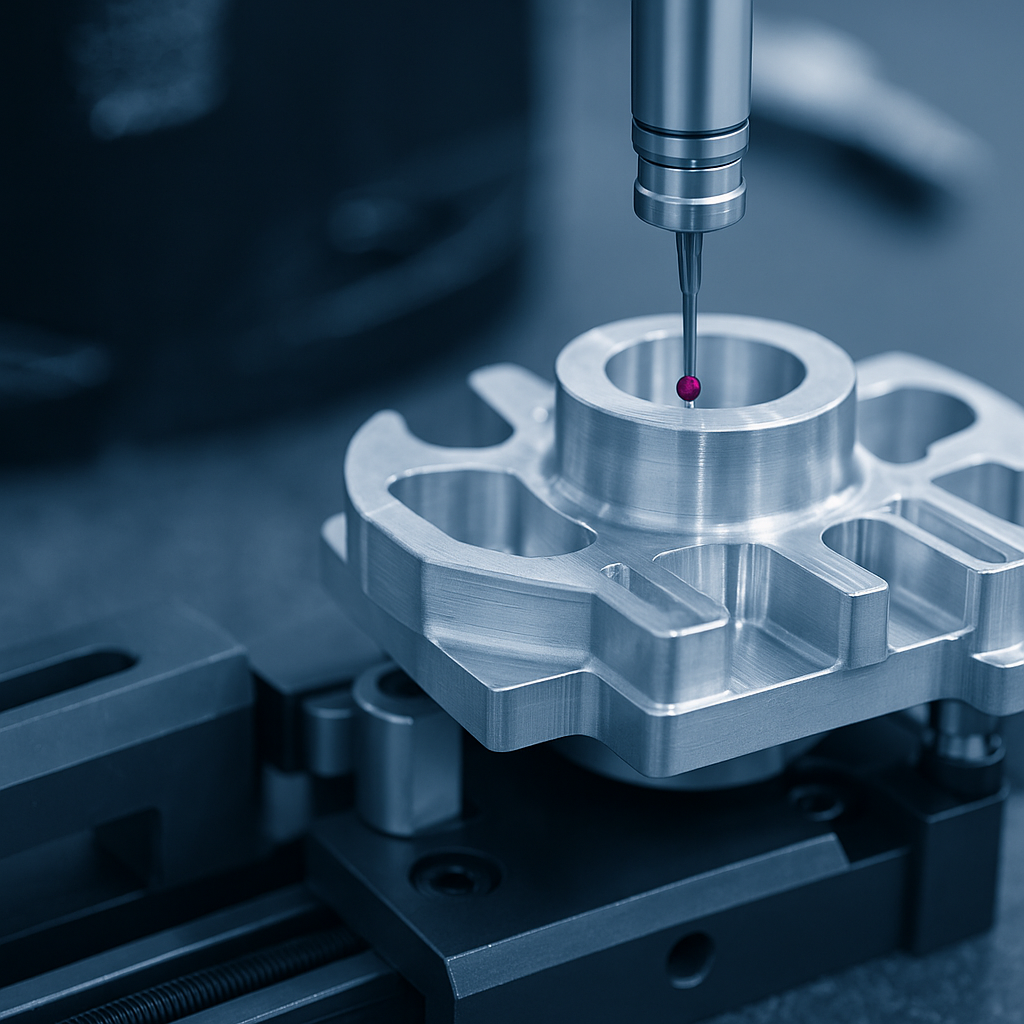

Advanced Inspection Capabilities

Our metrology department is equipped with state-of-the-art inspection tools that enable us to validate even the most critical dimensions and tolerances. We invest in modern technologies to ensure fast, accurate, and repeatable measurements for both prototypes and serial production.

- Coordinate Measuring Machines (CMMs) for 3D dimensional analysis

- Optical measuring systems for non-contact inspection

- Surface roughness testers for finish and texture control

- X-ray analysis for internal structural validation (on request)

Certifications and Compliance

Vormetal operates according to internationally recognized quality standards. Our processes are aligned with ISO 9001:2015 requirements, and we continuously update our practices to comply with sector-specific expectations in automotive, aerospace, medical, and industrial markets.

Customer-specific quality documentation such as PPAP (Production Part Approval Process), FAI (First Article Inspection), and IMDS (International Material Data System) submissions are available as part of our service offering when required.

Continuous Improvement

We believe that excellence is an evolving target. Vormetal continuously analyzes production data, customer feedback, and internal audits to drive improvements in process capability, product consistency, and operational efficiency. Our goal is to deliver the highest quality parts, on time, every time.