Tooling & Prototyping

What We Offer

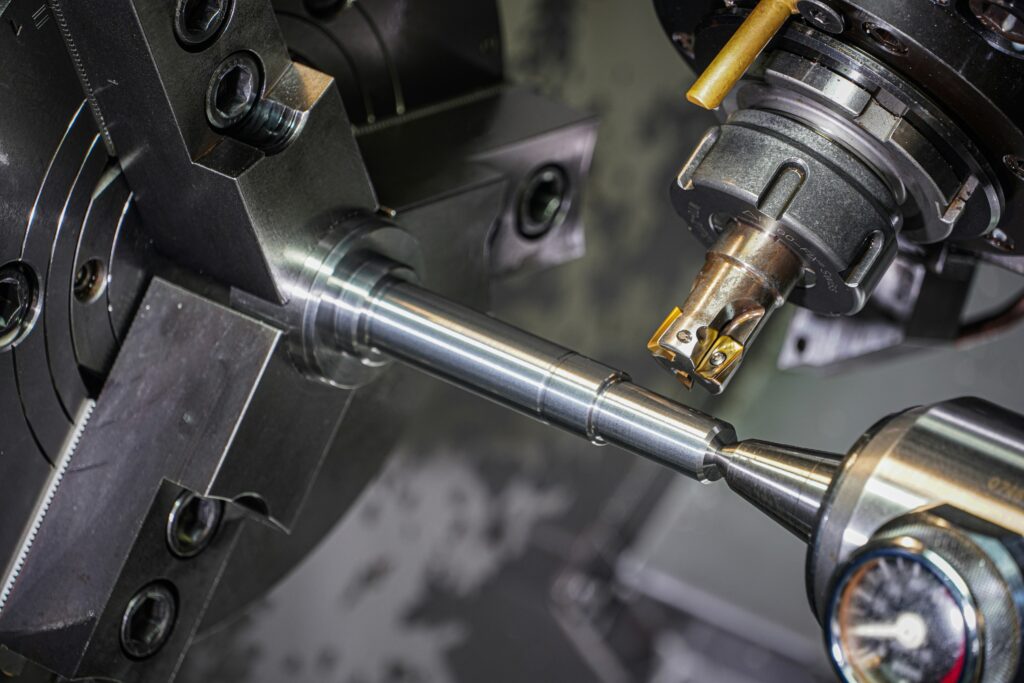

At Vormetal, we understand that high-quality parts begin with high-precision tools. That’s why we offer a complete in-house tooling and prototyping service. We handle everything from concept to cavity. This enables faster lead times, greater design flexibility, and unmatched control over part quality.

Whether you’re in the early design stage or preparing for mass production, our expert team works closely with you. We ensure your die casting tools are optimized for performance, longevity, and repeatability.

Custom Tooling Design & Manufacture

Our engineers design and manufacture custom molds and dies tailored to your part geometry, material selection, and production volume. All tooling is developed with:

- High-grade steel for durability

- Advanced mold flow simulation to predict casting behavior

- Tight tolerance control for dimensional accuracy

We handle both single- and multi-cavity tooling, with configurations optimized for aluminum and zinc alloys.

Rapid Prototyping Services

- CNC-machined prototypes from aluminum or alternative alloys

- 3D printed mockups for early design feedback

- Bridge tooling for small batch testing before full die build

We support your product development with fast and accurate prototypes. This helps you validate form, fit, and function before committing to full-scale production.

Faster Lead Times Through Vertical Integration

Because we manage everything under one roof, from tool design and manufacturing to final casting, we eliminate third-party delays and ensure:

- Shorter project timelines

- Real-time design iterations

- Streamlined communication

Why Tooling and Prototyping Matters

High-quality tooling directly affects:

- Part consistency

- Cycle time efficiency

- Surface finish quality

- Tool lifespan and maintenance frequency

By investing in robust and optimized tooling, we help our clients achieve cost-effective production with fewer defects and higher yield.

Designed for Manufacturability

We offer early-stage Design for Manufacturability (DFM) consulting to ensure your part design is optimized for the die casting process. From draft angles to wall thicknesses, our engineering input reduces revisions and speeds up production ramp-up.

Start Your Project with Confidence

Whether you need a one-off prototype or full production-ready tooling, Vormetal has the technical expertise. They have the responsiveness to bring your project to life—on time and to spec.